Plastic Types: Polycarbonate

The Steel of Plastics: Polycarbonate

In this installment of our plastics series, we discuss polycarbonate, or PC. Although the thermoplastics we’ve covered to this point have their gifts and talents, you’re not likely to hear “Polyethylene saved my life!” Polycarbonate, though, is another story. It literally saves lives—the guys on Mythbusters rely on it, so it must be cool.

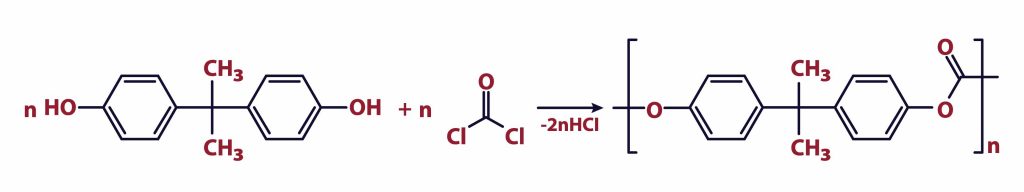

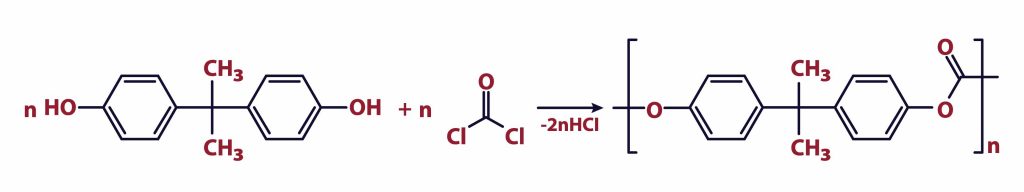

Developed independently in the early 1950s by scientists at General Electric in the United States and Bayer in Germany, PC entered industrial production in the late 1950s. It is usually discussed as one material, but there are actually two types of PC, one a thermoplastic and one a thermoset, each produced by a different process. The thermoplastic version, called polycarbonate of bisphenol A, begins life when bisphenol A is reacted with sodium hydroxide to transform BPA into a sodium salt form; this is then reacted with phosgene (usually), kicking off a series of reactions that eventually yield the clear PC resin. The thermoset version is created by polymerizing a monomer of carbon, hydrogen, and oxygen molecules to render a highly crosslinked molecular structure. (A thermoset plastic is one that cannot be remelted and reformed—it gets molded or extruded or what-have-you and that’s it.)

Polycarbonate’s Powerhouse Properties

Thermoplastic is the more common form, and it is the material of choice for products and parts that need the highest impact resistance possible. How high? Fighter-jet windshield high, bulletproof-vest high. PC is used to make both these products and others in which impact resistance is a matter of life and death.

One of thermoset PC’s interesting properties is light refraction; it bends light more strongly than glass, so it is used to make prescription eyewear. Those old Coke-bottle glasses were actually extremely heavy; PC made them a thing of the past. It can even be used for strong prescription contacts.

All this, and it’s affordable too. It is a common material for injection molding, but—as with any plastic—it isn’t suitable for every product. You won’t choose it if you’re creating a new line of pet grooming products, unless of course you need a bulletproof comb (in which case you probably shouldn’t have pets).

The big names in polycarbonate

Some well-known makes of PC resin are Makrolon and Lexan, both made by Covestro. Other manufacturers in this space include Celanese Corp., AdvanSource Biomaterials (for medical-grade uses), BASF, Mitsubishi, Sabic Innovative Plastics, and OmniPlastics, among many others.

Recycling PC

Thermoplastic PC is a material, like ABS, that is labeled with a 7, meaning it falls under the category of “other plastics” and is not necessarily accepted by your local recycling facility. PC, however, is highly reusable, and once it makes its way to collection points, it is a desirable material for regrinding and reselling back into manufacturing channels—it just isn’t necessarily easy to get it to the appropriate collection points.

In 2016, researchers at IBM discovered a one-step process for recycling PC that actually yields a plastic that is both more temperature and chemical resistant than the original and does not leach BPA.1 This has the potential to revolutionize the reuse process of thermoplastic PC and keep millions of pounds of it out of landfills every year.

1 Garcia, Jones, et al. (2016). Computational and experimental investigations of one-step conversion of poly(carbonate)s into value-added poly(aryl ether sulfone)s, Proceedings of the National Academy of Sciences (113)48.

Jenifer Wolfe

Consulting Editor

Jennifer Wolfe has a curious mind and a gift for words and languages—if she does say so herself. A trained metalsmith and lifelong craft nerd, she loves handmade stuff, whimsical clothes, and traveling. A resident of Mexico, she is certain that tacos are the food of the gods.